CenturionPro®

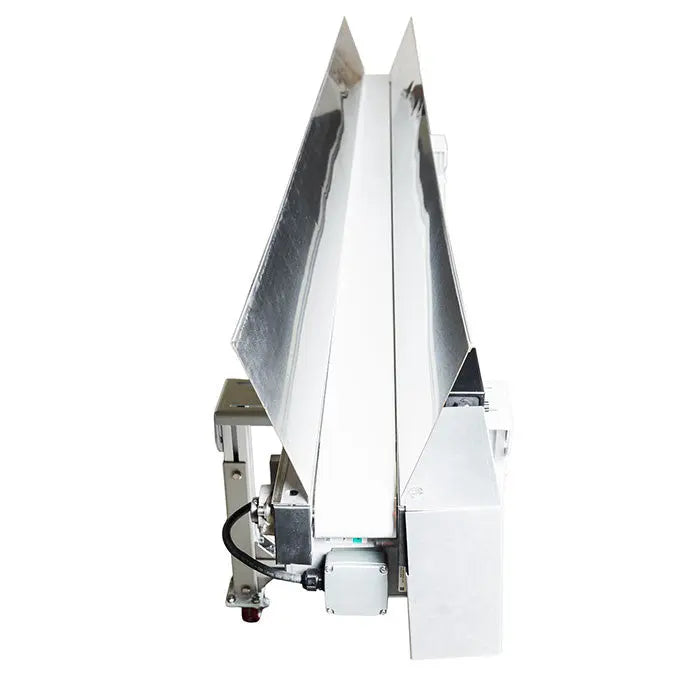

HP3 Gentle Cut Bucking Machine

The HP3 Triple Bucker provides triple the production capacity of the HP1, resulting in the industry’s highest buck rate per hour.

This bucker utilizes two rollers per workstation that pull the stem into the machine, therefore popping the flowers off.

Complete with three workstations, the HP3 Triple Bucker is a multi-operator-run industrial de-stemming machine that requires 3 operators for optimal speed and efficiency.

HP refers to "High Performance" and represents our workhorse line of buckers, which include single and triple-workstation options.

The high production value of these machines results in the industry’s highest buck rate per hour.

The HP line utilizes two rollers that pull the stem into the machine, therefore popping the flowers off.

This allows you to continuously feed the bucker for more efficient de-stemming.

Feed Throughput

- HP3: 500 lbs/hr (Wet)

- Feed Entry Sizes HP3: (3/16", 1/4", 3/8", 1/2", 3/4")

- Primary Material: 304 Stainless Steel / Aluminum

- Feed Types: Wet & Dry

- GPM/UL/CE/RoHS Compliant

Triple your throughput the the HP3 Bucking Machine

The HP3 Triple Bucker provides triple the production capacity of the HP1, resulting in the industry’s highest buck rate per hour.

This bucker utilizes two rollers per workstation that pull the stem into the machine, therefore popping the flowers off.

Complete with three workstations, the HP3 Triple Bucker is a multi-operator-run industrial de-stemming machine that requires 3 operators for optimal speed and efficiency.

Each workstation has 5 different sized holes to provide versatility and improve processing capacity.

The HP3 Triple Bucker accepts stems up to 3/4” in diameter and can buck 500+ pounds per hour of fully hydrated flower (100lbs dry flower).

This triple-headed machine comes with a bucker stand included for added value and ease of de-stemming. The bucker stand comes standard with industrial casters.

When combined with the high productivity of a CenturionPro trimming machine, you’ll get the highest capacity harvesting system in the world!

The HP3 Triple Bucker comes complete with three 0.75 HP gear-driven motors with a variable speed controller to provide unsurpassed power, adjustability, and control.

Thanks to the variable speed controls, wet or dry flower can be processed with ease!

The system is easy to set up and is made of stainless steel and anodized aluminum making it robust as well as easy to clean.

The HP3 Triple Bucker plugs into a 110 volt, 20 amp circuit – EU/AUS compatible. Backed by a 5 years warranty.

The HP3 Triple Bucker is quickly making a name for itself as the highest capacity bucker in the world!

This bucker is simple, powerful and effective and will process product at an unprecedented rate

Preparation for using the HP Buckers & Tip for Dry Bucking

Environment Preparation

- Ensure adequate space

- Review electrical requirements

- Have adequate bins for product transport

- Cooler temperatures in processing room is beneficial

Plant Preparation

- Cut main stalk

- Separate each individual stem (no 'y' junctions)

- Leave 3" of stem for clearance into machine

- Ensure clean angled cuts for precise feeding

Feeding

- Keep prepped product stem side up for efficiency

- Size the stem to fit the ideal hole

- Feed end first into machine

- Use variable speed control to adjust flow

Moisture Content

- Moisture content is critical for ensuring minimal damage to the flower

- Flower that is too dry will fall apart

- Flower that has too much moisture will compact and dent

- For best results with dry bucking, moisture content should be between 12% and 14% when using a machine

Bud Consistency

- Buds should be "springy"- when the flower is squeezed between two fingers it will rebound and return to its original shape

- Both big and smaller stems must be pliable when bucking with a machine such as a GC or HP System

- Pliable stems ensures that they fold and are stripped upon entering the bucking machine. If too brittle, they will simply break off and will not be properly stripped

Machine Speed

- Slowing the machine speed for dry bucking will lead to a better result

- Dry bucking at 1/2 or 1/3 of the regular speed will ensure better results

- The variable speed control offered by our HP Bucker is a great feature when bucking dry material

Out-feed Conveyor Upgrade

Enhance your elite harvesting solution with both infeed and outfeed conveyors.

Compatible with all CenturionPro’s trimmers, infeed and outfeed conveyors with variable speed controllers boost trim control and, therefore, trim quality.

In-feed conveyors ensure steady product delivery to trimmers, for consistent movement through the technology resulting in consistently superior results.

Out-feed conveyors afford growers greater opportunity to inspect these results, to ensure every single flower, regardless of shape, size or density, is trimmed perfectly.

HP3 Bucker Manual PDF

HP3 Bucker Conveyor Manual PDF

|

Model

|

HP3

|

|

Input Voltage

|

120V, 60Hz, Single Phase

|

|

Current Draw

|

7.5A Operating

|

|

Motor

|

0.75HP, IP54 (x3)

|

|

Motor RPM

|

1690 RPM (x3)

|

|

Weight (w/ stand)

|

471 lbs / 214 kg

|

|

Length

|

93 in. / 236 cm.

|

|

Width

|

32.5 in. / 83 cm.

|

|

Height

|

52 in. / 130 cm.

|

|

Circuit Breaker Required

|

20A/120V

|